BWXT Engineering Intern

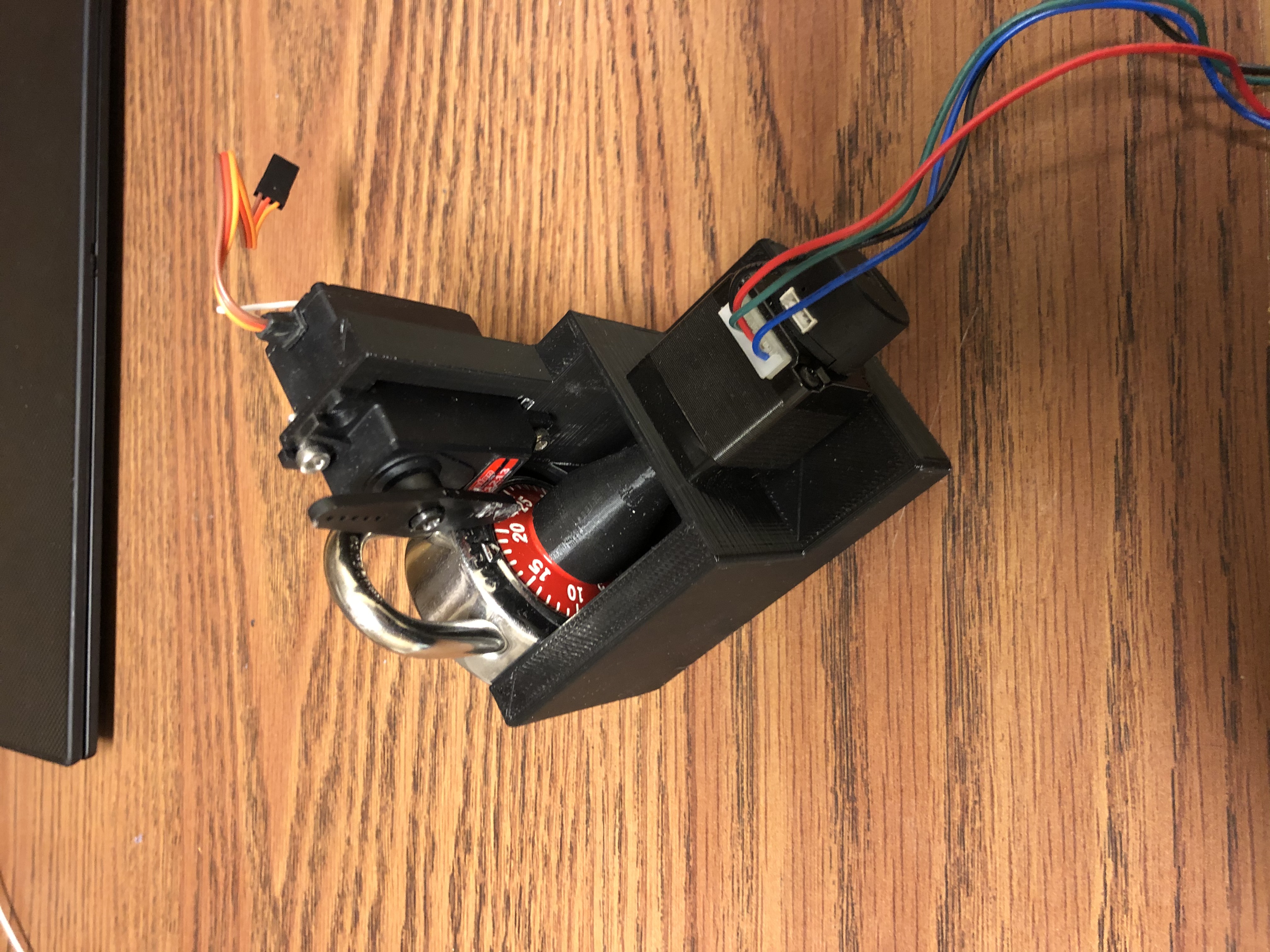

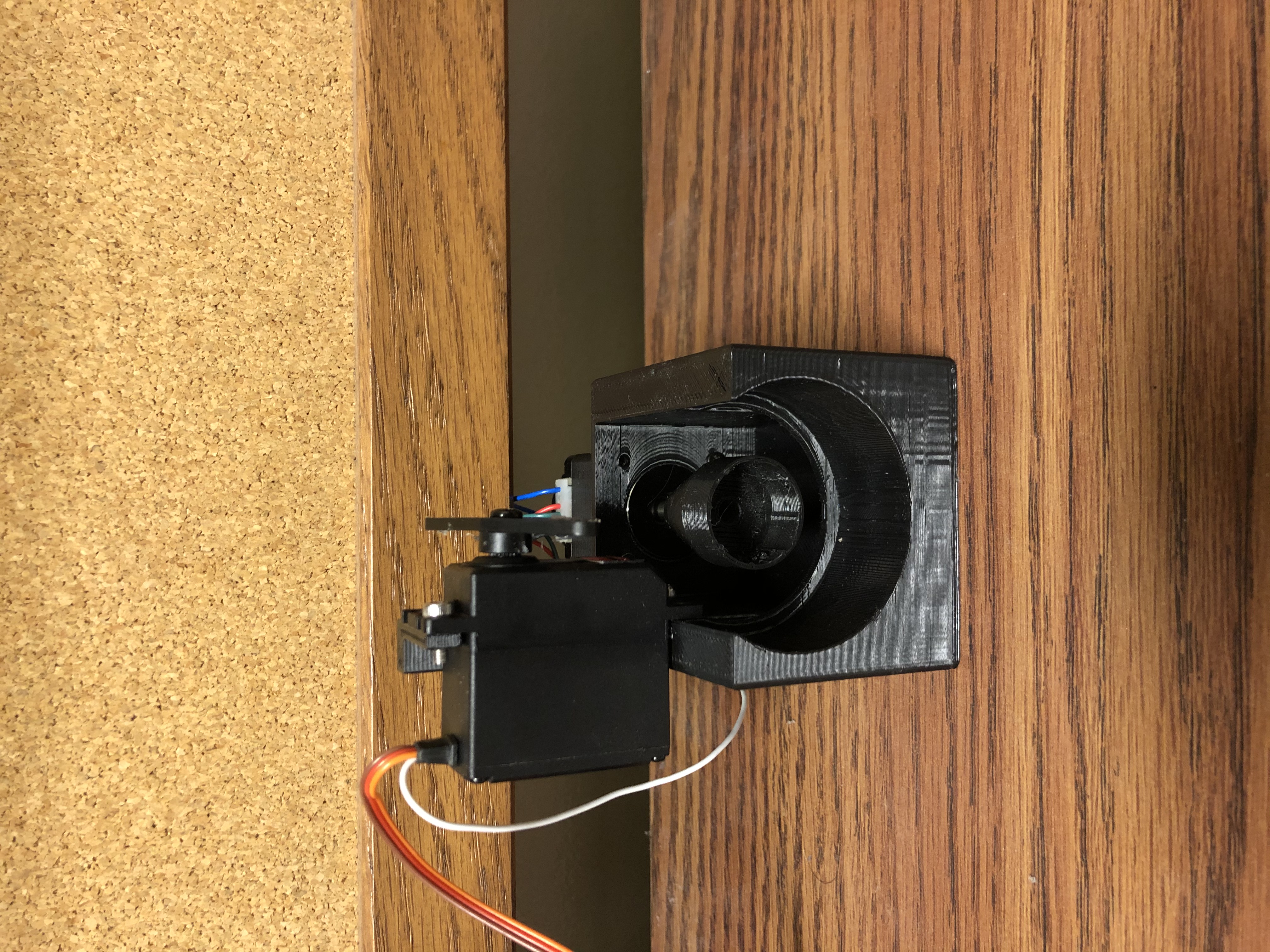

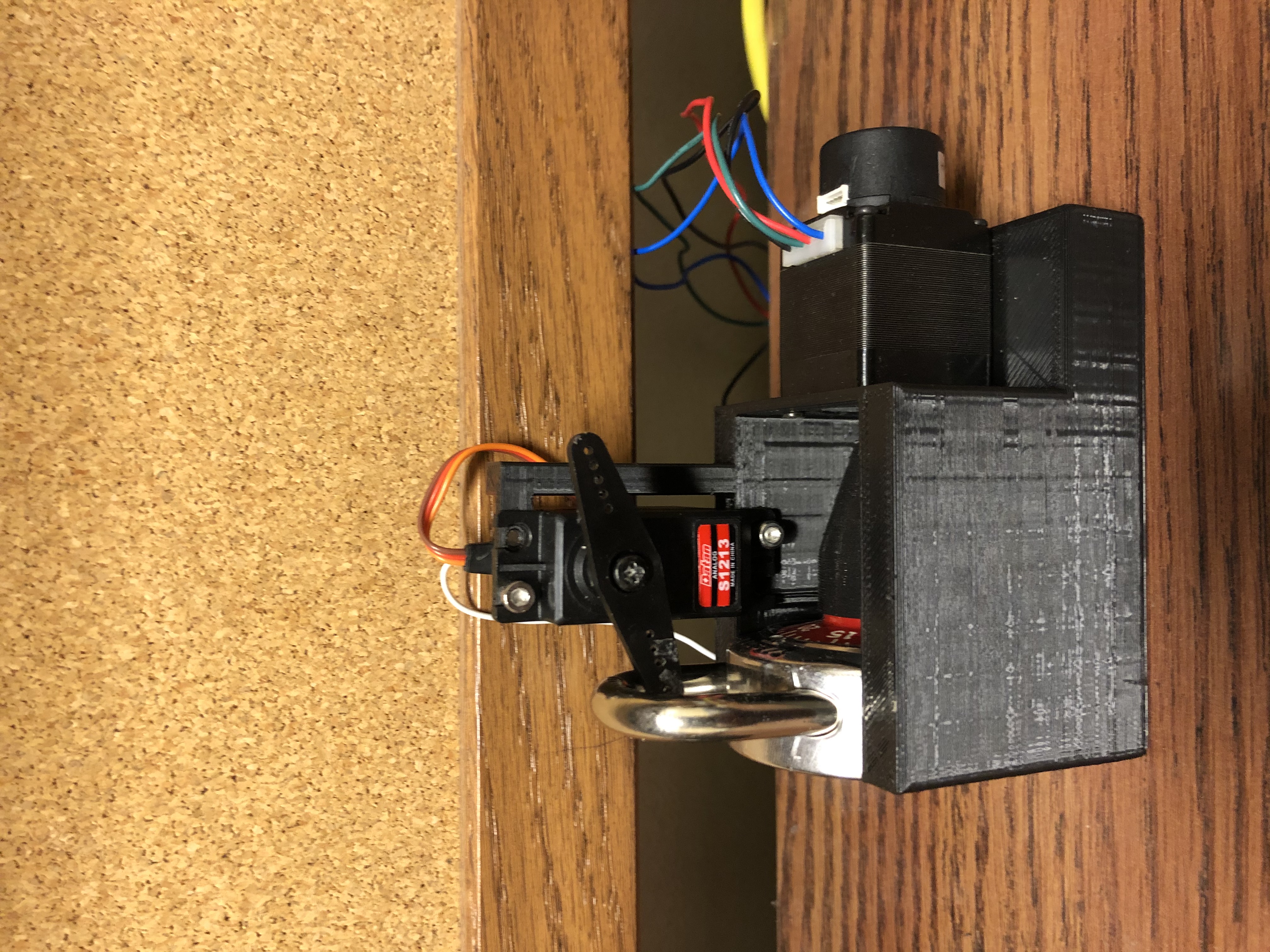

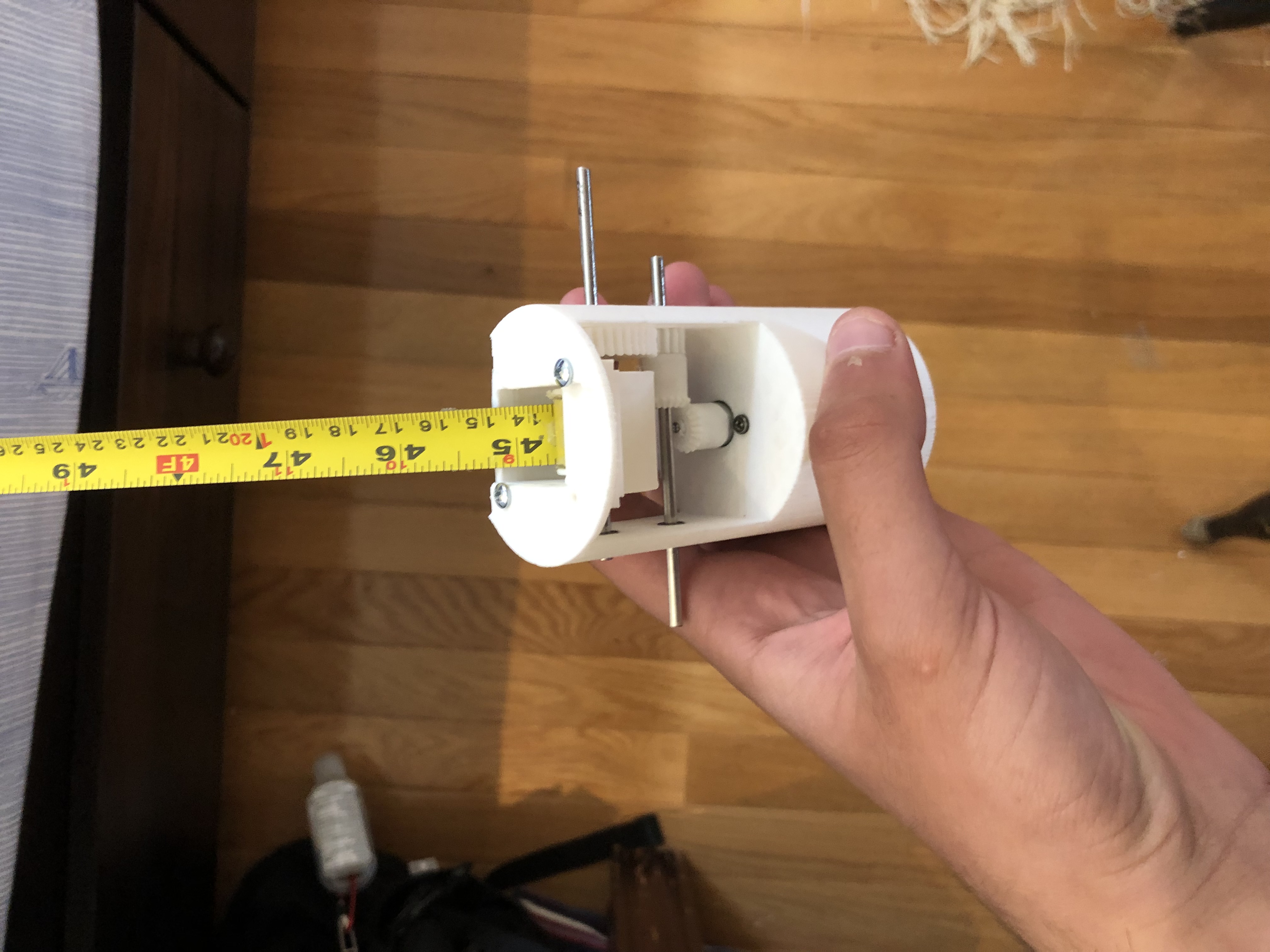

I worked at BWXT as an intern from August to September of 2022. For this internship I had gained a DOE-L Security Clearance and was working in the Non-Destructive Evaluation Group. In this group I worked with mostly Ultrasonic Immersion testing and help design transducer probe mounts and build an entire UT scanner system that was small and portable. I learned a lot about UT scanning and its usefullness for the company. I was also able to help develop a invention for UT aid. We are currently in the process of filling the invention as a patent for the company and therefore I am working part time to help with filing it.